The Largest Domestic Manufacturer of Microchannel Coolers

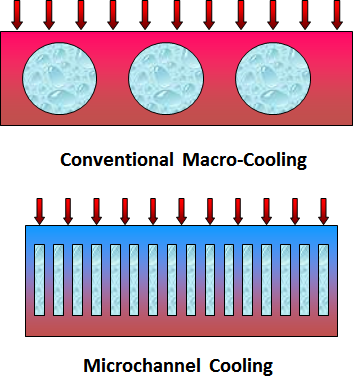

The Largest Domestic Manufacturer of Microchannel Coolers MC2 offers a broad range of thermal management solutions for the electronics, laser diode, and aerospace industries. These solutions include micro-impingement and microchannel coolers and coldplates, heat spreaders and heatsinks, heat pipes, and compact air/liquid and liquid/liquid heat exchangers. MC2 products can be applied anywhere demanding thermal environments are found - we specialize in cooling components exposed to high temperature and/or high heat flux environments.

MC2 is best known for the world-class cooling performance of our micro-impingement/microchannel cooler line, with passage widths as narrow as 12.5 microns. More than 50,000 coolers have been built and sold to date. These coolers have been tested for over 2000 hours with no degradation of thermal performance. They are tough, and attachment of laser diodes or other components is straightforward. Please see our cooler pages for more detailed information.

MC2 is best known for the world-class cooling performance of our micro-impingement/microchannel cooler line, with passage widths as narrow as 12.5 microns. More than 50,000 coolers have been built and sold to date. These coolers have been tested for over 2000 hours with no degradation of thermal performance. They are tough, and attachment of laser diodes or other components is straightforward. Please see our cooler pages for more detailed information. Other thermal management products are available as well, including heat exchangers, condensers, evaporators, and recuperators.

Other thermal management products are available as well, including heat exchangers, condensers, evaporators, and recuperators. Actively Engaged in Federally-Sponsored R&D

Actively Engaged in Federally-Sponsored R&D MC2 also has a strong R&D component, having served as a prime contractor on projects for NASA, DARPA, and the US Army, Navy, and Air Force. MC2 also Please see our R&D pages for more information.