Products

R&D

- Integrated Fuel-Air HX for Turbine Engines

- Cryo HX w/Anisotropic Conductance

- Advanced Turbine Blade Cooling

- Small Rocket Motors

Services

Ultra-Compact Heat Exchangers

MC2's compact heat exchangers use laminated foil construction to reduce the core size and weight of Air/Air, Liquid/Liquid and Liquid/Air heat exchangers.

Advantages of Laminated Foil Heat Exchangers

- Improved Thermal Performance

- Reduced Scale of Passages Yields Higher Heat Transfer Coefficients

- Large Heat Transfer Area Per Unit Volume

- Compact Construction

- 5X Core Depth Reduction Compared to Conventional Concepts

- 3X Weight Reduction

- Robust Construction

- Laminated Foil Heat Exchangers Use a Reinforced, Robust Construction

- Almost Any Metal Can be Used (Cu, Al, SS, Superalloys, etc.)

- Structures Can be:

- Soldered (Low Cost)

- Brazed (for Aluminum)

- Diffusion Bonded (Higher Strength, Longer Fatigue Life, Reduced Corrosion Potential)

.

Previous Heat Exchanger Development Programs

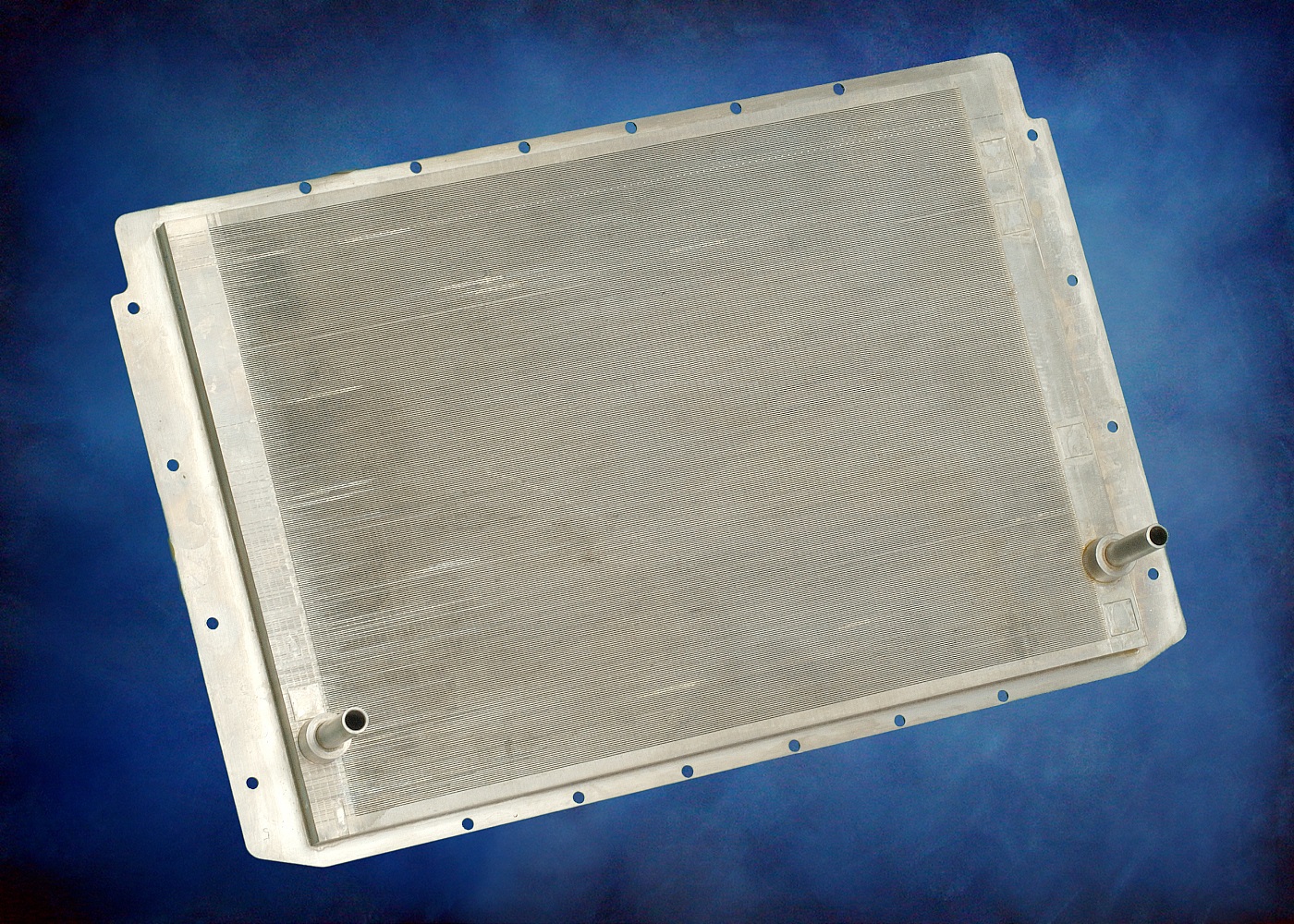

| Application | Material | Core Size | Image |

|---|---|---|---|

| Recuperator for Gas Turbine Engine (2009) | 304SS | 10” x 13” (Elliptical Annulus) | |

| Microchannel Condenser for Military Ground Vehicles (2008) | Glidcop | 6” x 6” x 8” (Quarter-Circle Annulus) |  |

| Air-Liquid HX for DARPA High Energy Laser (2007) | 304SS | 6” x 3” x 2” |  |

| Air Force Fuel-Air Heat Exchanger for Cooled Cooling Air (2000) | Waspaloy | 1.5” x 1” x 2” |  |

| LMSMSS Space Station IPU Heat Exchanger (1999) | 347SS | 9" x 13" x 0.5” |  |